Winter, especially farther away from the equator, equals white landscapes and that time of the year to cozy up to a fireplace. To us humans, winter is just another season. But to buildings, roads, bridges, and many other types of concrete structures, winter is a time to suffer the worst type of distress: the freeze-thaw cycle effect.

What is the freeze-thaw cycle and how does it happen?

There are 2 ways this phenomenon occurs in nature. The first is through the repeated cycle of melting and freezing of water on the natural cracks and grooves of rocks, such as in mountains, tundra and the like.

The second phenomenon occurs when the surface layer of rock is baked by direct sunlight, such as in desert regions. This top layer will expand and contract repeatedly, causing distress and eventually, cracks.

Can’t visualize the end result of years of distress and erosion? Example: think The Grand Canyon – mighty beautiful, but we want our human-made structures to stand proud and strong for years.

What are the types of distress concrete structures face due to weather conditions?

Dry concrete can suffer from both types of distress, either by freezing and thawing of water or its expansion and contraction under extreme daily temperature variations. Due to the geographical locations of certain cities like Dubai and Toronto, these types of distress cannot be avoided. However, concrete can better withstand the effects of both phenomena with a little help from additives.

What is the freeze-thaw cycle in concrete?

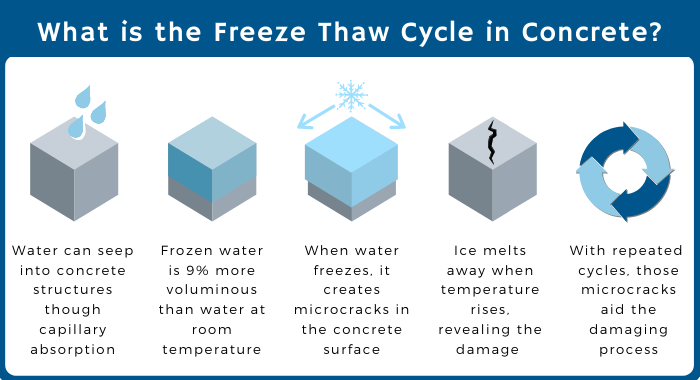

The freeze-thaw phenomenon occurs when concrete is saturated with water and the temperature drops, freezing the H2O molecules. Since frozen water expands 9% of its original volume, it causes distress to the concrete structure. Once the warmer months come by, the H2O molecules melt away and reveal tiny cracks in the surface layer of the structure. The following winter when those tiny cracks are filled with water once again and the temperature drops, the H2O molecules expand, making more room for themselves and causing more distress in the concrete structure.

The continuous freezing and thawing of water causes those tiny cracks to become larger over time. If not repaired – or prevented by additives in the concrete mixing phase – will permanently damage the structure.

Why does the freeze-thaw effect damage concrete?

Distress and damage to concrete from this phenomenon happens when concrete is heavily saturated with water, which happens when more than 90% of its pores are filled with H2O. Added to the fact that frozen water occupies 9% more volume than water at room temperature and there is limited space for the volume increase within dry concrete, the freezing of water causes microcracks. This damage begins from the first cycle of the freezing and thawing of water and with continuous exposure to winter seasons, will result in repeated loss of the concrete surface.

In a nutshell, this phenomenon is a process of distress that concrete experiences through the cyclical freezing and melting of water that has seeped into it. Over time and without proper care, this cycle can cause total cracking and permanent damage to the concrete structure.

How to identify the damage caused by the freeze-thaw cycle in concrete?

Often the diagnosis of the effects of this phenomenon is complex. Complications arise since other mechanisms may be involved, such as the Alkali-Silica reaction (ASR). But if all other mechanisms can be excluded, the typical signs of the freeze-thaw cycle could be:

- Spalling and scaling of the surface,

- Surface parallel cracking,

- Large chunks are coming off the surface of concrete, visible to the naked eye,

- Exposure of uncracked aggregates,

- Gaps around the aggregate.

How to avoid the freeze-thaw cycle damage to concrete?

The short answer is: air. It sounds so simple, but if there are built-in “expansion chambers” within concrete, the structure would have room to accommodate the 9% increase in the volume of frozen water. Thus, the distress, damage and cracks to the concrete surface would be minimized by entraining air in concrete through additives.

What is air entrainment in concrete?

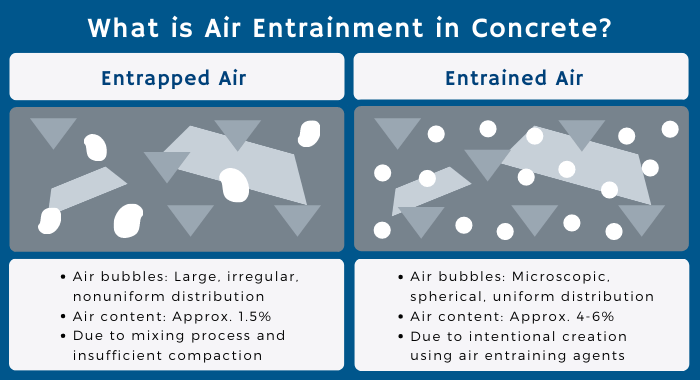

There are 2 kinds of air in concrete, entrapped and entrained. Entrapped air results naturally from the mixing process, with approximately 1.5% of air becoming trapped when concrete is being made. The entrapped air bubbles are easily seen with the naked eye and irregularly shaped. Due to their shape and larger size, entrapped bubbles do not help to protect concrete from the damage of the freezing and thawing of water.

Unlike trapped air, entrained air is created by design. Entrained air bubbles are the opposite of entrapped air, since they are innumerous, spherical, and microscopic. Usually, the well-distributed bubbles have a distance of approximately 0.25 mm between each other. Thus, depending on the application, approximately 4% to 6% air by volume is needed in concrete to achieve the necessary air bubbles to act as expansion chambers to accommodate the freeze-thaw action of water.

So, in order to protect concrete from damage, concrete should be air-entrained by adding an air entraining agent to its mix.

What are some commercial air entraining agents available in the market?

There are various air entraining agents in the market with different chemical and physical properties. The air entraining agents Polytrade has in its portfolio for concrete applications are part of the Carbofen product line. Our products are compatible with other materials and used solo or combined with other substances in concrete admixture formulations. The Carbofen product line for concrete additives consists of:

- A plant-based product, Carbofen Resin;

- Carbofen Admix, a liquid concrete additive; and

- The powerful water-soluble powder, Carbofen NCX.

Why invest in an air entraining agent for concrete?

Air entraining agents can reduce the maintenance costs of repairing cracks in concrete caused by the freeze-thaw cycle and increase the overall longevity of the structure. Not limited to only 2 benefits, these powerful materials are used for 3 primary reasons:

- Create concrete that is freeze-thaw resistant,

- Prevent bleeding in concrete, and

- Reduce the water/cement ratio.

1) Creating freeze-thaw resistant concrete

The first and foremost reason is to entrain air in concrete and make it freeze-thaw resistant. Or in other words, make concrete more resistant to the effects of repeated freezing and melting of water in colder climates. Also, air entraining agents are valuable additions to concrete mix design in tropical climates, since they minimize the stress concrete faces with extreme thermal variance.

2) Preventing bleeding

Secondly, air entrainers prevents bleeding. Bleeding occurs when water rises rapidly to the surface of freshly placed concrete and the slow evaporation of water is essential to cure concrete properly. Thus, the right distribution of water within the poured concrete is essential for the longevity of the structure.

3) Reducing the water/cement ratio

Lastly, air entraining agents reduce the water/cement ratio of concrete. As a general rule of thumb, concrete with high water content and high water to cement ratio is less frost resistant than concrete with lower water content.

Questions?

Let us know by commenting below or get in touch with our team of experts!

Don’t forget to comment and share this blog post with colleagues on our LinkedIn company page.

Published on 21-DEC-2018. Last updated on 07-APR-2021.

1 thoughts on “What is the Freeze-Thaw Cycle in Concrete?”

Comments are closed.