The development of lightweight, stable mortars with excellent mechanical performance is one of the great challenges of modern civil engineering. In this context, the additive Carbofen NCX, developed from natural resins, has proven to be an innovative and effective solution for formulations that require high workability, water retention, lightness, and above all, consistent mechanical strength over time.

By incorporating air in a controlled manner into formulations, Carbofen NCX significantly reduces the density of mortars, making application easier and reducing material consumption per square meter. This controlled air incorporation, combined with the stability provided by the additive, allows the developed mixes to achieve excellent surface finish, proper adhesion, and high compressive strength—even with high air content. This balance between lightness and strength is a key differentiator, especially for applications such as internal and external rendering, base coats, technical plasters, and thermal-acoustic mortars, among others.

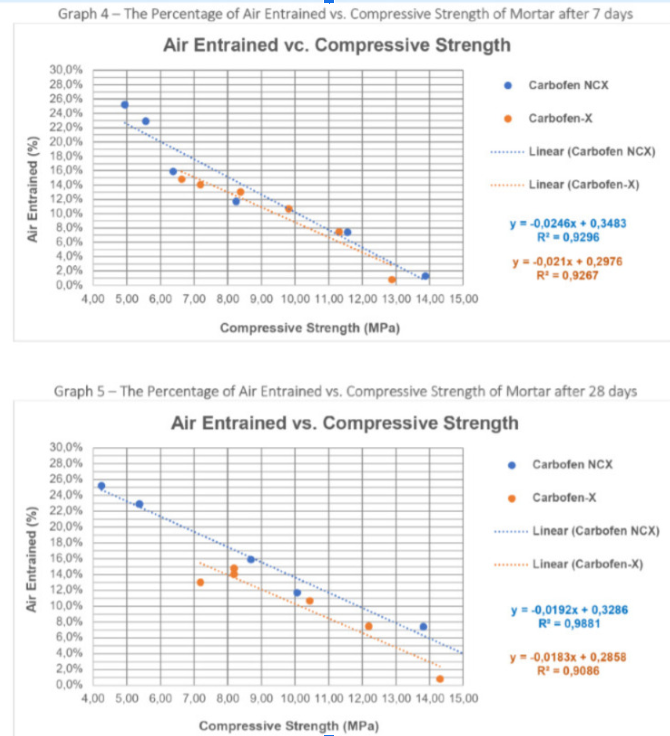

In comparative performance tests, different formulations with Carbofen NCX were prepared, varying the additive dosage to observe its influence on air incorporation and, consequently, on the mechanical performance of the mortars. The results were remarkable. With air contents above 20%, the mortars maintained excellent compressive strength, exceeding 4 MPa at 28 days of curing—a high benchmark for lightweight mortars.

The compressive strength results at 7 days showed a good balance between lightness and early performance, with a coefficient of determination (R²) of 0.9296 between air content and strength. This index shows a predictable relationship between the air incorporation promoted by NCX and the mortar’s mechanical performance. At 28 days, this relationship became even more stable, with an R² of 0.9881, indicating consistency and reliability in the additive’s performance throughout the curing time.

In addition to technical performance, another important aspect of Carbofen NCX lies in its natural and renewable base. Derived from plant tannins, NCX not only improves mortar performance but also contributes to the sustainability of construction projects. Its formulation avoids the use of aggressive synthetic additives and aligns with environmental requirements and the principles of sustainable, low-impact construction.

Another positive point is NCX’s compatibility with different types of cement and mineral additions. Tests indicate that the additive performs well in formulations with CP II and CP V cements, and is also compatible with limestone fillers, metakaolin, fly ash, and other pozzolanic materials. This makes it a versatile technical solution for the industrialized mortar industry and batching plants seeking additives that offer stability and predictability across various formulations.

The workability of mortars with NCX is also noteworthy. Even with high air content, the formulations maintain good cohesion, low bleeding, and excellent water retention. This facilitates both manual and mechanical application, reduces rework on-site, and enhances performance under varying climatic conditions.

Another benefit observed was Carbofen NCX’s good compatibility with other chemical additives. In tests with plasticizers, water reducers, and set retarders, NCX showed positive synergy, enhancing expected effects without compromising the stability of the mix. This allows mortar companies to fine-tune their formulations more technically and efficiently, tailoring mixes to suit the final application needs.

When it comes to cost-benefit, the use of Carbofen NCX is justified not only by technical advantages but also by the indirect savings on-site: reduced material consumption, easier and faster application, fewer defects, and increased durability of coatings. The additive’s superior performance can reduce maintenance and rework costs, resulting in real gains over the construction’s lifespan.

The additive also offers great storage stability, with low hygroscopicity and high solubility in water, making it easy to handle and incorporate into industrial processes. Its dosage is flexible, typically ranging from 0.1% to 1% of the binder weight, allowing for fine adjustments to the mix based on desired density and strength.

Beyond technical and practical aspects, Carbofen NCX reinforces the commitment to innovation in civil construction, offering a more sustainable and technically advanced alternative for high-performance formulations. Its use is already expanding across various segments of the precast, lightweight coating, sealing block, and cement artifact industries, with highly positive results in the field.

In summary, Carbofen NCX represents a significant advancement in the development of modern mortars. Its combination of lightness, strength, stability, and sustainability makes it a smart choice for companies seeking technical performance with environmental responsibility. Whether in large-scale works, industrial projects, or innovative building systems, NCX is a reliable and efficient solution to meet the challenges of contemporary construction.